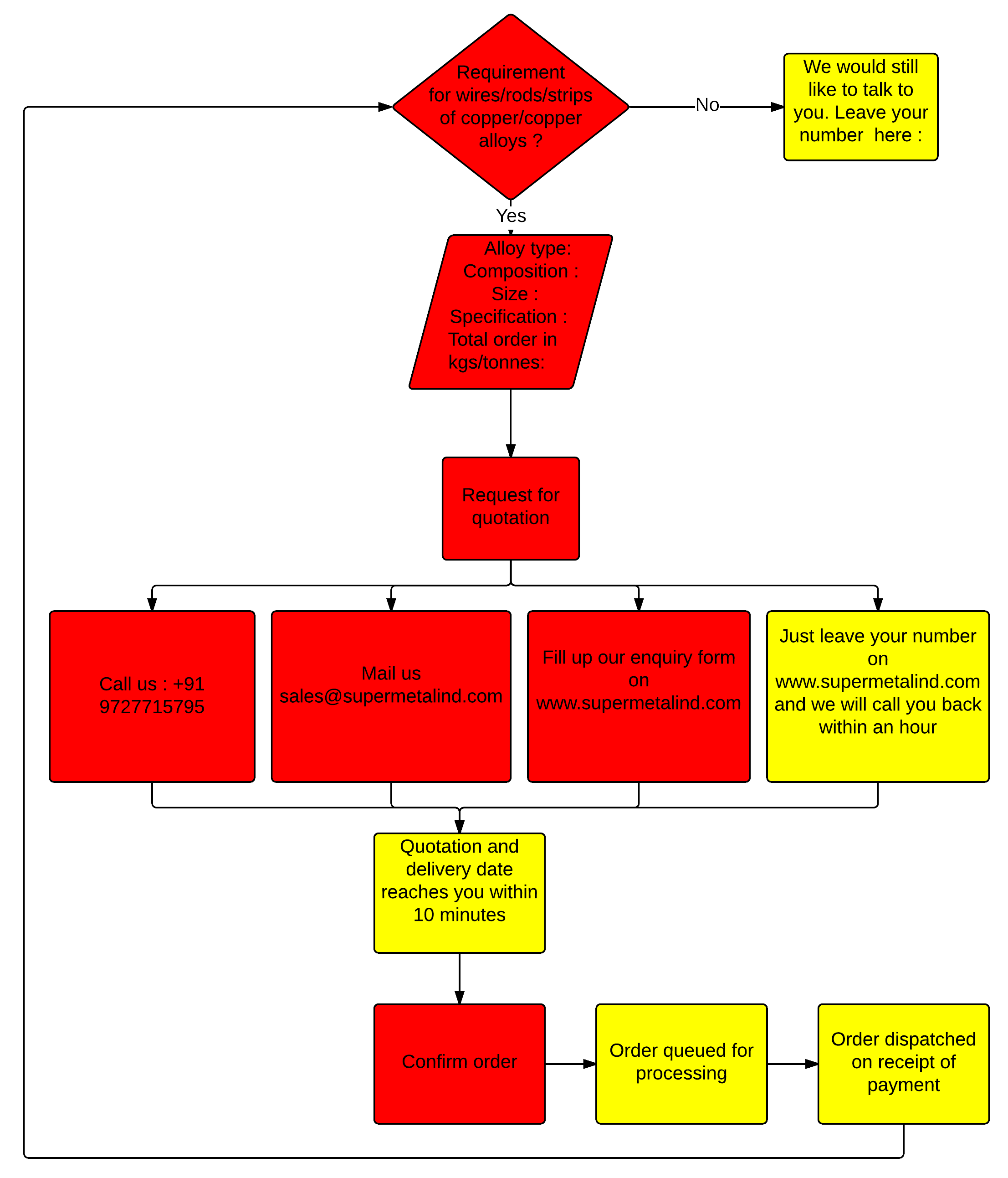

Delivery Process

Super metal industries has steadily grown under the able leadership of Mr. Bharat Goradia, who has been in the field of non-ferrous metals since 1960. Backed by years of experience and nonpareil expertise, SMI is today, one of the leading manufacturers of high quality precision brass wires, copper wires and phosphor bronze wires. SMI has achieved the status of being the “most preferred” manufacturer by its clientele, not just because of its commitment towards personalized services and timely delivery, but also superior quality of its products.

SM ploughs a huge percentage of its profits in research and innovation, which reflects in its machinery and testing equipment, built to achieve both quality and precision.

Quality planning and schedule

At SMI, we have a Quality management system (QMS), wherein we perform regular quality checks on our products that leave the house. We follow scheduled processes that includes both

Per dispatch quality check

This includes scheduled testing of each order that is dispatched from the manufacturing unit for

- weight

- hardness

- composition

- ductility

- malleability

Random sample quality check

This includes further rigorous testing of our products by picking samples from the dispatches and testing both the physical and chemical characteristics of the product. Some of the equipment we use on our samples include

- Optical Emission Spectrometer

- Universal Testing Machine

- Hardness Tester Machine

- Conductivity Meter

- Metallurgical Microscope

- Eddy Current Testing Machine

- Hydraulic Pressure Testing Machine

- Chemical Lab testing